- HOME

- Brand

- Quality

In forging process, metal moved while it is still in the solid state. King Tony specialized in forging technology to create better metal configuration. Non-straight grain flow and non-sharp corners can extend lifetime and durability of socket. Torque is transmitted for powerful tightening under safety.

Tools are made to extend hand work. King Tony selects different material depends on its difference of nature for tightening, power impacting, cutting, rotating, and locking. Choose qualified material to meet required lifetime for professional use and consumption.

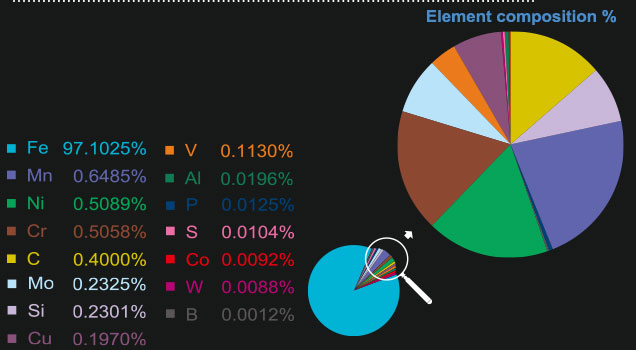

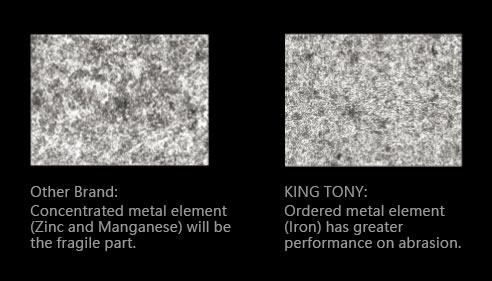

Heat treatment involves the use of heating or chilling on experience and time control. King Tony controlled heat treatment systems to ensure the right hardness without the brittleness. From microstructural picture you can see elements are well- distributed.

Heat to take shape and complete fibers to improve durability

Remove oxide layer and ensure sockets roundness for follow process precision

Control sockets external diameter and the roundness

Drilling pin hole on the groove to offer impact socket safety operation

Finish complicated process to ensure product the precision

Remove the burrs and chamfer on square hole

Make accurate dimension for the spanner

Stamp dimensions, material and manufacturer

Enhance product performance to achieve max. hardness

Remove oxide layer and burrs for surface coating

Remove oxide layer and burrs for surface coating

Nickel-chrome plated to protect product from corrosion and improve finish

Increase impact sockets wear resistant and prevent corrosion to improve the durability

The unique bi-colors silk printing design and is easy to distinguish metric and inch dimension

The unique bi-colors rubber stripe design and is easy to distinguish metric and inch dimension

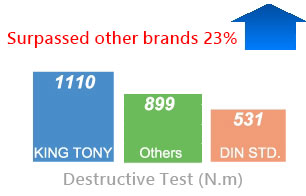

Quality control also ensure that a sufficient level of production output. King Tony uses advance technology to inspect tiny difference on each step. Our hand socket, ratchet, extension bar, and power handle is 30% higher than international DIN standards. Impact socket reach 50% higher torque than DIN standards.

1/2DR. 19mm hand scoket (433519MR)

1/2DR. 19mm hand scoket (433519MR)

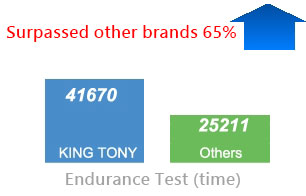

King Tony offers reliable tools for professional users, strictly controls its quality to ensure achievement of required performance. From “fracture & fatigue test”, you will know the difference we have when compare to others.

Metal material elements analysis

Measure the screw tap to meet LEVEL I tolerance of DIN standard.

Test the productÕs hardness to meet KING TONY quality standard.

48 HRs environmental simulation test to check productÕs durability from being rusty.

Apply special chemical to check thickness of plating and ensure it reaches KING TONY Ôs standard.

Fracture test to check the max. torque to ensure excess of DIN standard.

Cut for a smooth section

In order to fix tiny and multilateral workpiece

Make surface of workpiece smoother and clearer for further observation.

Analyze the change of metallography after heat treatment and the difference of hardness between surface and central location.

Simulate temperature from 70 °C ~ - 20°C to test product reaction and durability while obvious change of temperature.

Test pulling force of product especially for joint workpiece according to DIN standard.

Test the lifetime of striking hammer and security of the joint of hammer& wooden shaft.

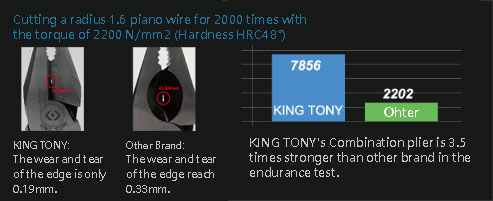

Test the cutting force and durability.

Follow the DIN ISO & ASME standard to test torque tolerance by 3 points of 20%, 60% and 100% of max. scale.

Test products with smaller torque such as bits for their durability.

Measure parts for difficult angle or in the narrow space.

Test the strength of carton in order to assure good packing quality.

Ensure products are insulated under the voltage 1000V.

Registered color identification system is smart innovation for tool history. King Tony built the sockets in two colors - BLUE for metric size, RED for imperial size- make selection much easier. Extend idea for tool storage and management help professionals save time.

High-grated tools with minimum tolerance make a greater difference on skilled maintenance.

A greater hardness at the edge makes it very sharp and easy to cut. Wear-resistant design is for different purposes pliers and cutters. Our high leverage combination pliers quality is tested by cutting piano wire with sharp performance.

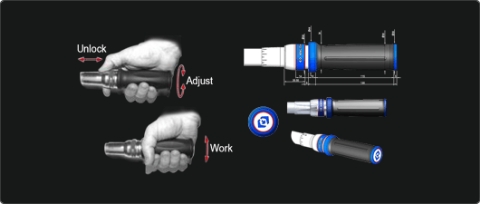

There are more and more improved tool structure comes out every year. King Tony selects useful idea and engineering function on developing new product within quality and economic concern. Every piece of component is designed for the comfort to users.

The continuous movement in professional job always brings fatigue and muscle tension. And it results increasing discomfort or injury to the users. King Tony treats the health and safety of the users as first majority of concern. We try to design a more comfortable and safe handling on the products. For example, we select TRB insert molding process to supply better and safer handling for working.

Less affect by environmental considerations to every aspect of the product lifecycle including planning, design, choice of materials, manufacturing, distribution, usage, and recycling. King Tony always follows the rule of relative standard such as RoHS the European standard for non-toxic and recyclable contents. We concern the environment and human while we supply the best quality tools.

The quality is one of the most important things and is taken care since the beginning of design. King Tony makes details clearly on 2D dimension engineering drawing & 3D shape picture communicate on production. We create mold precisely to make sure satisfaction of designed performance. Then after checking and testing from trial production, we arrange mass production for on-time delivery to global customers.