Clase de Introducción a Las Herramientas

Clase de Introducción a Las Características y Ventajas de Las Herramientas

Clase de Operación y Aplicación de Herramientas

Clase de Mantenimiento y Reparación de Herramientas

- Mantenimiento del Almacén de Herramientas 1

- Mantenimiento de Mano y Accesorios 4

- Mantenimiento de Herramientas Neumáticas y Dados de Impacto y Accesorios 5

- Mantenimiento de Los Alicates 0

- Mantenimiento de Herramientas Para Tuberías 0

- Mantenimiento de Herramientas Electrónicas y Eléctricas 0

- Mantenimiento de Las Herramientas del Taller 0

- Mantenimiento del Alumbrado 0

- Mantenimiento de Herramientas de Automoción 1

Clase de Certificadas y Comprobación de La Calidad de Las Herramientas

Introducción del Torque de Herramientas

Área de Servicio de Marketing

Conocimientos Básicos

Popularidad : 330El Posicionamiento y Segmentaciones de Mercado de las Herramientas Manuales

| Segmentación del Mercado | Posicionamiento | Cliente Objetivo |

|---|---|---|

| Nivel de Bricolaje | Para usos generales. |

|

| Nivel Profesional | El nivel básico de herramientas manuales profesionales. |

|

| Nivel Industrial | El nivel superior de nivel profesional y requiere una mayor calidad de los productos. |

|

| Nivel Aeroespacial | Más alto que el nivel industrial y tiene el estándar más estricto en la calidad de los productos. |

|

Diferencias entre ‘Hexagonal‘ y ‘Ranura‘

-

Horarios:

El hexágono es una forma tradicional, pero la de doce puntas es mucho más popular a pesar de que se inventó más tarde que el hexágono.

-

Funciones:

Más ángulos significa grados más pequeños que cada ángulo será, por lo tanto, se requerirán menos grados de rotación al colocar las herramientas en los tornillos.

-

Especificaciones:

La función y la especificación de los ranura y el hexágono son exactamente iguales. El interior dentado se puede insertar firmemente en la cabeza de los pernos o tuercas, además, también se denomina ‘Anillo‘ debido a la apariencia similar entre un anillo y la llave de boca de doce puntas.

El marco rojo en el gráfico 1 representa el hexágono y el marco negro representa los ranura. Después de superponerlos, el resultado muestra que se puede utilizar un ángulo más en cada superficie del hexágono.

Graph 1

¿Cuál es la función del ángulo de la llave?

La selección del ángulo de las llaves requeridas se basa en los entornos de trabajo o la profundidad de los tornillos que se insertan en las máquinas.

El problema de la incomodidad se presenta a menudo al usar llaves debido a los entornos de trabajo, los espacios o la posición de las máquinas que deben repararse. Por lo tanto, para aumentar la accesibilidad y la conveniencia, las llaves están diseñadas con múltiples ángulos que permiten a los usuarios realizar diversos trabajos.

Las llaves rectas son adecuadas para desmontar tornillos en superficies planas.

Elige las llaves según la profundidad.

Aplicaciones de Diferente Cantidad de Dientes de Trinquetes

KING TONY proporciona trinquetes con cinco tipos de dientes.

La diferencia más significativa entre diversos dientes son los grados de rotación.

El grado de circunferencia es de 360 grados. Cuanto mayor sea la cantidad del ángulo, menor será el grado de cada ángulo. El gráfico 2 y el gráfico 3 ilustran que el grado de cada ángulo será de 5 y 15 grados respectivamente cuando los trinquetes tengan 72 dientes y 24 dientes.

Gráfico 2

Gráfico 3

Gráfico 4

Mérito:

La dirección debe girarse para ajustarse al ángulo de los tornillos o casquillos hexagonales mientras se trabaja. Cuanto menor sea el ángulo del diente, menor será la necesidad de rotar las herramientas. Tome la mecánica de vehículos como ejemplo, al reparar vehículos en un espacio estrecho, se producirá el problema de la inconveniencia de girar en un ángulo grande debido al espacio de trabajo reducido.

La ventaja de la baja cantidad de dientes:

Como demuestra el gráfico 4, el engranaje y los componentes izquierdo y derecho están en conflicto entre sí, lo que implica que cada diente puede tener una superficie mayor cuando el número de dientes es menor, y la estructura será más fuerte y sólida.

Tipos de Puntas y Dados de Punta

Se pueden dividir en varios tipos según el cabezal de las herramientas.

Botón de liberación rápida (QR.)

Separados, según la característica, en ‘QR. Tipo‘ y ‘No QR. Escriba‘.

Aparte del botón de dirección en el cuerpo principal que puede controlar la dirección de rotación entre el sentido de las agujas del reloj y el sentido contrario a las agujas del reloj, un botón redondo, que es el QR. botón, puede controlar el montaje y desmontaje de los enchufes.

-

Presiona el QR. botón entonces la bola de acero se sumergirá para reducir la resistencia de instalar el zócalo.

-

El zócalo no se puede desmontar sin el QR. botón que se está presionando, lo que puede evitar los accidentes que podrían ser causados por resbalones.

Aplicar el casquillo es aumentar la fricción entre el casquillo y todo tipo de adaptadores, como barras de extensión o carracas. Las ranuras de retención de bolas están diseñadas dentro del orificio cuadrado para evitar la circunstancia de sacudidas cuando se instala el casquillo.

Las ranuras de retención de bolas se pueden combinar con la bola de acero en los adaptadores y el QR. El botón está diseñado exactamente para estas ranuras.

El QR. botón debe presionarse en ambas situaciones de instalación y desmontaje del zócalo. El diseño de seguridad puede reducir la ocurrencia de accidentes cuando se trabaja en altura.

Enlace a E-Learning de KING TONY ”Conocer los Dados de Mano y de Impacto” para saber más~

Clasificación sencilla e Introducción de Herramientas

Separados, siguiendo la fuente de energía de la fuerza motriz, en dos tipos, que son la fuerza humana y la fuerza de la maquinaria.

| Fuerza motriz | Categorías de productos | Diferencias | ||

|---|---|---|---|---|

| Par de Torsión | Velocidad | Precio | ||

| Fuerza Humana | Herramientas Manuales | Débil | Lento | Barato |

| Fuerza de Maquinaria | Herramientas Neumáticas | Fuerte | Rápido | Un poco empinado |

| Herramientas Eléctricas | Medio | Rápido | Caro | |

| Herramientas Hidráulicas | Extra fuerte | Lento | Caro | |

Uso de Herramientas Manuales

Uso de todo tipo de llaves.

| Tipos | Uso | Medio Ambiente | |

|---|---|---|---|

| Llave Abierta - 1900 Llave Anillo - 19C0 Llave Inglesa Combinada - 1062 |

Para apretar o aflojar tornillos o tuercas hexagonales exteriores que se utilizan para fijar y sujetar. Algunas llaves se suministran con 45 grados y 75 grados para poder llegar a los tornillos o tuercas en diferentes profundidades. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

| Tipo L Llaves Hexagonales - 1130MR | Para apretar o aflojar tornillos hexagonales interiores. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

| Llave ajustable - 3611 | Para apretar o aflojar tornillos o tuercas hexagonales exteriores que se utilizan para fijar y sujetar. Notablemente, el tamaño del extremo de uso se puede ajustar. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

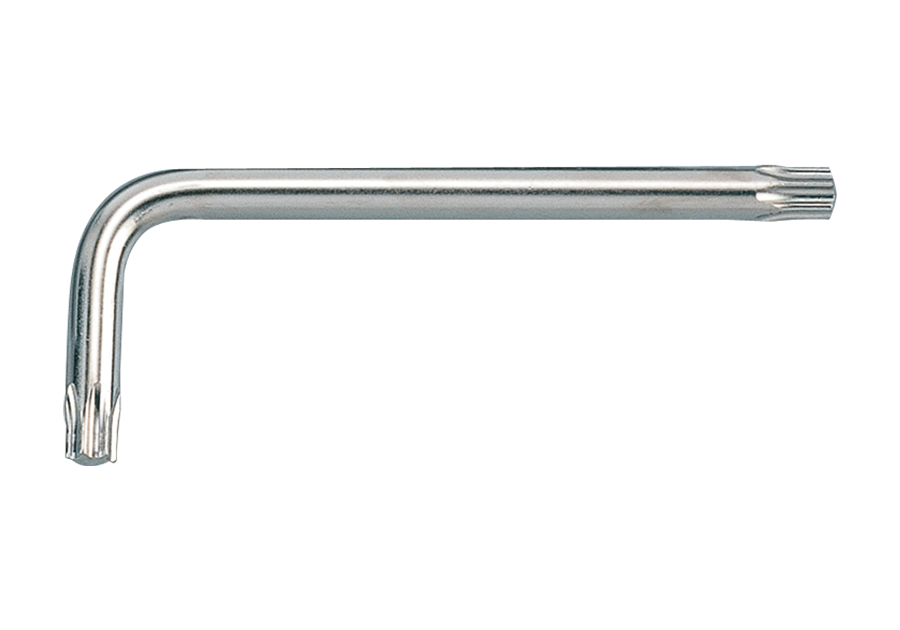

| L Estrella - 1143R | Para apretar o aflojar tornillos hexagonales interiores. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

| Llave Dado Angulo - 1081 | Para apretar o aflojar tornillos o tuercas que se utilizan en la fijación y sujeción en la industria de la arquitectura. | Normalmente se utiliza en fábricas, reparación de automóviles y maquinaria agrícola. | |

| Llave Rapida - 3730M | Para apretar o aflojar tornillos o tuercas que se utilizan en la fijación y sujeción. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

| Llave Tuerca - 1930 | Para apretar o aflojar tornillos o tuercas que se utilizan en la fijación y sujeción de las tuberías de aceite. | Normalmente se utiliza en fábricas, reparación de automóviles e industrias de locomotoras. | |

Enlace a E-Learning de KING TONY ”Llave inglesa” para saber más~

Destornilladores

Uso de todo tipo de Destornilladores.

| Tipos | Uso | Medio Ambiente | |

|---|---|---|---|

| Destornilladores generales - 1422 1421 |

Para montar y desmontar tornillos. | Normalmente se utiliza en industrias regulares y reparación de máquinas. | |

| Destornilladores de Electricista - 1472 1471 |

Para montar y desmontar tornillos en lugares con electricidad o lugares que son fáciles de recibir una descarga eléctrica. | Normalmente se utiliza en lugares con electricidad o lugares que son fáciles de recibir una descarga eléctrica. | |

Enlace a KING TONY E-Learning ” Destornilladores y Puntas” para saber más~

Productos recomendados

Llaves de Velocidad Reversible

3732S

Llave con Anillo Acodado a 75°

1970

Llave de 6 Puntos para Tuerca de Ensanchamiento

1930

Llaves de Velocidad Flexible

3730M

Llaves de Velocidad

3731M

Llaves de Velocidad Reversible

3732M

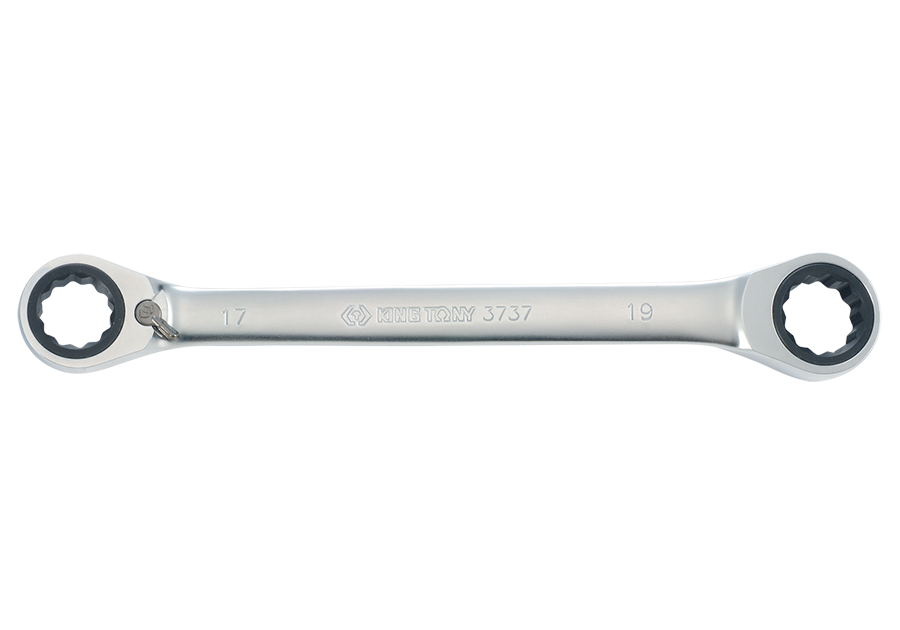

Llave de Velocidad de Extremo Doble

3736M

Llave de Velocidad de Extremo Doble

3737M

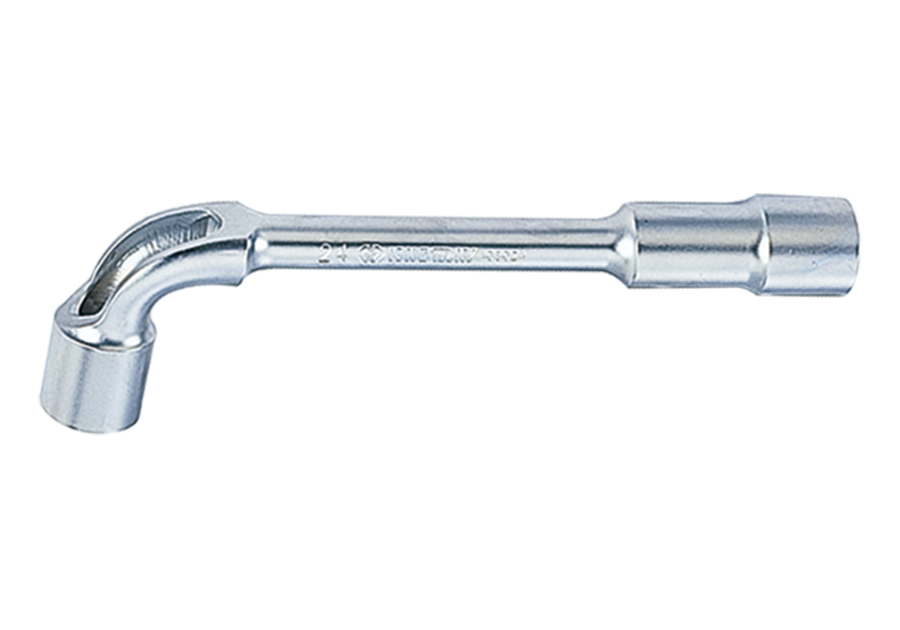

Llave Tubo en Ángulo de 6+6 Puntos

1081

Llave Ajustable

3611

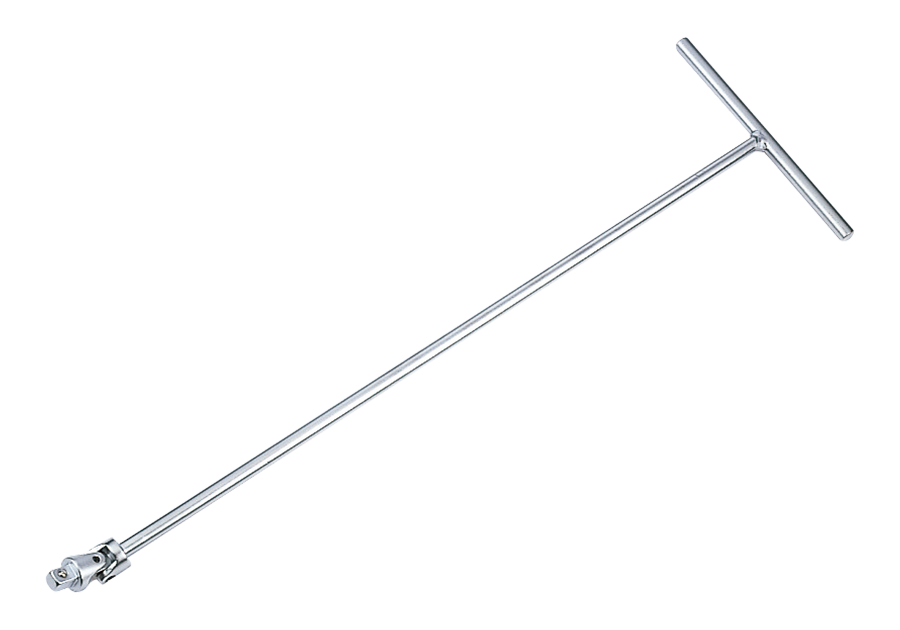

Conductor de Junta Universal en Forma de T de 1/2" DR.

4795

Llave Inglesa Combinada

1060

Llave Abierta

1900

Dado de 12 Puntos Profundo Métrico de 1/2" DR.

4230M

Dado de 6 Puntos Profundo Métrico de 1/2" DR.

4235M

Dado Estrella de 1/2" DR.

4375M

Llaves de Velocidad Abiertas

3721M

Junta Universal de 1/2" DR.

4791R

Llave Hexagonal Punta de Bola (Brazo Largo)

1130MR

Llave Hexagonal Punta de Bola (Brazo Largo)

1130SR

Llave Hexagonal Punta de Bola (Brazo extralargo)

1120MR