Tools Introduction Class

Tools Feature & Advantage Introduction Class

Tools Operation and Application Class

Tools Maintanence and Repair Class

Tools Quality Checking and Certified Class

Tools Torque Introduction

Marketing Service Area

Screw Extractor Set (Fine thread)

Popularity : 34325Features

Goal: To remove damaged screws.

Basic Principle: The direction of the thread is levorotatory. Screw the extractor into the damaged screw in levorotatory direction, and the damaged screw will be extracted by the rotation.

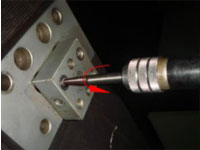

Operation: Drill a hole on top of the damaged screw initially. Utilize the extractor with a tap wrench. Screw the extractor into the hole in levorotatory direction, then the damaged screw can be removed.

Specifications

-

Material: SCM440

-

Heat Treatment

1. HRC40°~42° (M6、M8)

2. HRC42°~46° (M11、M14)

3. HRC45°~50° (M18) -

Surface Treatment: Polish and black oxide.

| Size | Capacity (Imperial) |

Capacity (Metric) |

|---|---|---|

| M6 | 1/8"~1/4" | 3.25~6.35 |

| M8 | 1/4"~5/16" | 6.35~7.9 |

| M11 | 5/16"~7/16" | 7.9~11.11 |

| M14 | 7/16"~9/16" | 11.11~14.28 |

| M18 | 9/16"~3/4" | 14.28~19.05 |

Operating Steps

| 1 | 2 | 3 |

|---|---|---|

|

|

|

|

Demonstrating with an 8mm screw and M11 screw extractor. |

The situation of damaged screw may be encountered during the screwing process. |

|

| 4 | 5 | 6 |

|

|

|

|

In the beginning, use a spot drill to locate the position of the center. Due to the cross section is crooked and rough, using a regular drill might drill might end up with an off-center hole. |

Follow up with using a regular drill that is under 6mm. If using a drill that is over 6mm on an 8mm screw, the inner wall of the damaged screw might be torn while tapping and lead to the harming of the original thread on the damaged screw. |

Rotate in counterclockwise direction till the damaged screw is fully extracted. |

| 7 | ||

|

||

|

The damaged screw is removed successfully. |

||